STEPA builds hay cranes with a reach of up to 14 m and a lifting moment of 9.2 mt. The STEPA modular system provides a number of individual solutions. It is highly attractive in that there is an almost infinite number of possibilities. The perfect solution for your needs.

Agriculture

Overhead slewing cranes

Our products in action

The best-selling boom system with high speeds and smooth operation achieved by using plastic rollers and low-maintenance extension ropes. This system has been exceptionally successful at STEPA both for agricultural and forestry use for over 20 years. The compressive lifting cylinder of STEPA’s load arm means low oil warming at higher working speeds during lifting and lowering of the load arm.

Specifications

- Up to 12m horizontal reach and 15m vertical reach

- Low maintenance and hard-wearing

- Boom system with high driving speed

- S700 fine grain steel

- Compressive lifting cylinders for minimal oil use and maximum speed

- 2 energy-saving LED headlamps as standard

Technical information

-

Measurements

Extremely narrow stables could be equipped with a crane for the first time after STEPA brought the quadruple telescopic crane onto the market in 1997 as the first manufacturer of what was then the Quattro crane. It also became possible to reach distances of up to 15m horizontally and 17m vertically.

Specifications

- Extremely small model size for narrow stables

- Can replace a cross bridge

- Protected design up to end of grapple

- S700 fine grain steel

- Compressive lifting cylinder for minimal oil use and maximum speed

- 2 energy-saving LED headlamps as standard

Technical information

-

Measurements -

Technical information

Accessories

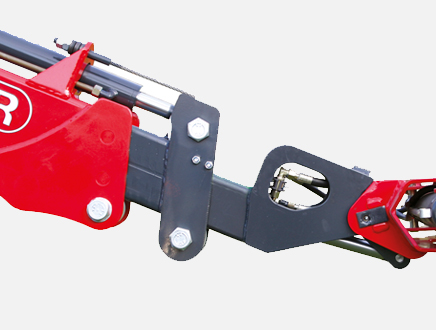

Rotation-Elevate-System

Our roation-elevate-system has all important compontents (ball bearing ring with slewing engine, distributor, hydraulic hoses and the lifting up cylinder) inside mounted. This leads to an optimal protected solution, equipped with a service cover and a simple and servcie friendly usage.

This system reduces the possibility of damages, is stronger with very compact dimensions.

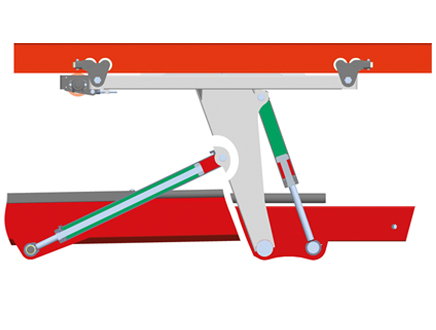

Compressive lifting cylinder

Not only does this compressive lifting cylinder need fewer litres of oil, it also achieves higher speeds, reduces oil warming, weighs less and has better handling characteristics. We are the only crane manufacturer to offer this benefit!

More information under "FAQ"

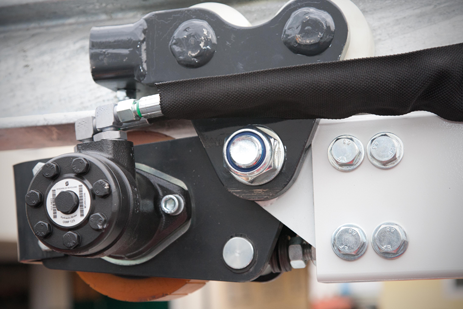

Telescopic system with rope

The rope extension system achieves higher speeds, runs more quietly and requires less maintenance. STEPA has used the tried-and-tested telescopic system both for agricultural and forestry use for over 20 years.

Combination joystick & radio remote control - work optimally

A combination of joystick and radio remote control, a proportionally piloted joystick control with 2 pedals and 2 joysticks or an electric joystick control without pedals - STEPA offers control variants for every price class and purpose.

90 l hydraulic tank

The large hydraulic oil tank is constructed to minimise use of space and also delays oil heating.

2 LED headlamps (more light, less heat)

Two high-quality LED headlamps not only provide a better cone of light, they also use less electricity and produce little heat.

Result: More light for less electricity and heat, as well as higher quality - comes as standard

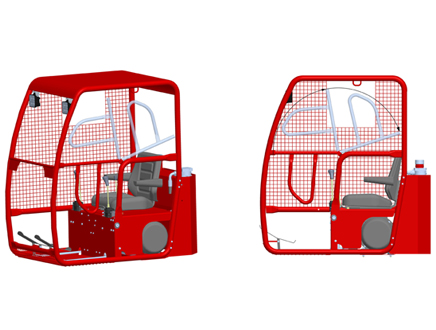

Glass floor and centrally arrange foot pedals with ball bearings

The toughened glass floor and the centrally arranged foot pedals allow a better overview downwards. Thanks to the ball bearings, the foot pedals can be operated easily and precisely.

Document compartment

A handy compartment for necessary documents.

High-strength S700 steel

High-strength steel by VOEST for STEPA, stands out for its high quality. The material is significantly stronger and more durable as seams are minimised.

Durable Vulkollan drive wheel instead of rubber wheel

A high-strength Vulkollan drive wheel has significantly lower wear than standard rubber wheels. This reduces maintenance costs.

More information under "FAQ"

Standard-compliant access & sound insulation in the cab roof

You can access all STEPA overhead slewing cranes by pushing back the bar. As such, the crane can be exited in an emergency regardless of its position. Sound insulation is installed in the cab roof, which significantly reduces noise and increases driving comfort.

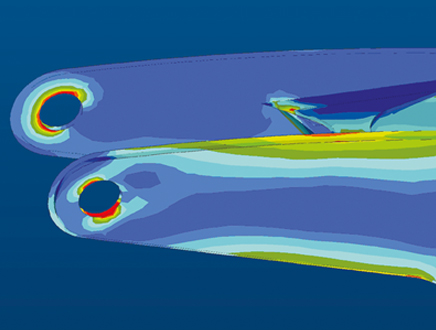

3D construction of all component parts

The construction of STEPA cranes is based on our decades of experience and supported by the use of the most advanced computer programs.

FEM calculation

STEPA cranes are developed and improved on the computer with calculations using the finite element method.

Frequently asked questions

This very important and difficult question depends on many factors.

Here is a short list of important factors to consider:

- Roof truss design

- Size of the building (required crane boom length)

- Particular circumstances (pit silo, ventilation boxes, etc.)

- Size of farm (average daily quantity in ha)

- Other specific requirements (radio remote control, curved rails, crosswise drive)

Based on these points and several more, we can establish - preferably in an on-site meeting - the possible variants for you.

Each crane is adapted for best results in specific conditions and to make work processes simple for our customers.

With the STEPA modular system, you can select from over 45 different crane types with a wide range of equipment variants.

The compressive lifting cylinder was introduced by STEPA in 2000. The lifting cylinder, which lifts and lowers the main boom, is found behind the crane column. For lifting, the cylinder must be “pushed” out. Previously, the cylinder had to retract to lift the load arm = a “pulling” cylinder.

Why did STEPA do this?

The compressive lifting cylinder has 7 significant benefits, which the pulling cylinder does not have.

Benefit 1: Lower oil consumption (136% less when lowering, 19% less when lifting). This means the pump has a greater residual capacity for other functions.

Benefit 2: Better handling performance, above all when carrying out multiple functions at the same time as less oil is used for the main function of lifting and lowering.

Benefit 3: The lifting boom no longer swings up. On the other hand, with a pulling cylinder, the pump cannot get sufficient oil into the cylinder compared to the amount that can flow out. This deficiency leads to the lifting boom encountering “holes” and swinging up. The only solution was to integrate throttles, which reduce the outflow of oil = heat and speed reduction.

NOTE: At high temperatures, the viscosity of the oil increases and the throttle must be set accordingly so that see-sawing of the lifting boom is reduced.

Benefit 4: No throttle required = no integrated oil heating.

Benefit 5: An oil cooler is not needed as quickly because throttles are not needed.

Benefit 6: Better crane geometry - STEPA uses the full piston area for lifting.

Benefit 7: The lifting cylinder is shorter and stronger - lower tare weight.

Ropes have the following

Benefits:

- No need for degreasing and lubrication

- Runs more quietly

- Ideal for tensile loads (see rope winch)

- Low maintenance

- Lower wear through low maintenance requirements

(The chain runs into the runner, increased wear if the chain is soiled, etc.)

Disadvantages:

- Larger space requirement due to larger deflection pulleys (approx. 16-18 times the rope diameter)

The larger space requirements are also the reason why ropes are not used in some areas, e.g. Palfinger Epsilon forestry and recycling cranes, forklifts, etc.

In these areas, the pull-in forces are significantly higher and using larger ropes is not an option as it results in significantly larger space requirements.

To that effect, the issue of greater space requirements has been solved by STEPA by using 2 ropes instead of a single rope for drawing in. For this reason, the deflection pulley does not need to be enlarged and it is possible to achieve a very high pull-in force.

Ropes have been used successfully in our agricultural and forestry cranes for 25 years in over 15,000 cranes.

For many years now, STEPA has used a drive wheel made from Vulkollan, which is considerably better though more expensive.

By using Vulkollan, STEPA sets standards with regard to durability and resistance to wear, as well as reducing maintenance costs.

For further information, please see the manufacturer and commercial companies’ websites.

You can find clear information on Vulkollan here: